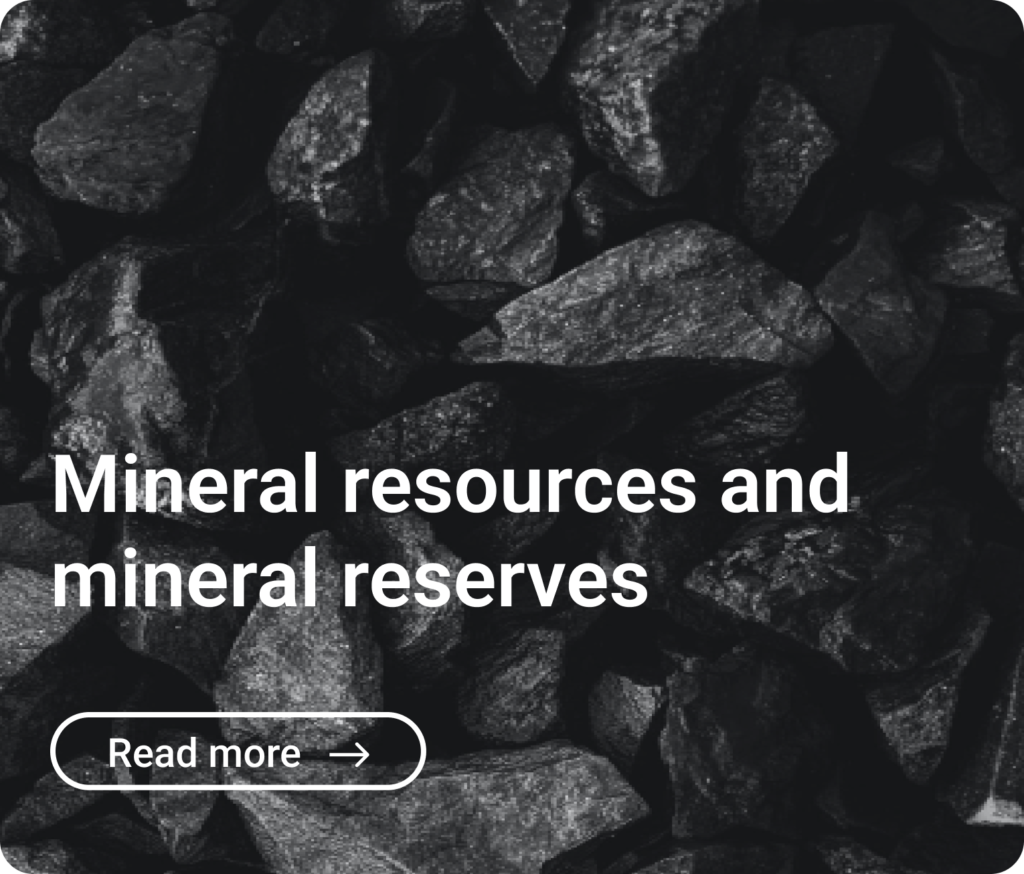

THE DANNEMORA PROJECT

GRANGEX Dannemora aims to be the first producer of high-quality iron ore concentrate in the European Union with the lowest carbon footprint. GRANGEX intends to restart the Dannemora mine in Östhammar municipality in 2025.

GRANGEX’s goal fulfillment takes place through a comprehensive requirement during project development that all equipment and all production methods – if practically possible – aim to eliminate emissions of carbon dioxide. All consumables such as hydraulic oils, lubricating oils and the like must be fossil-free.

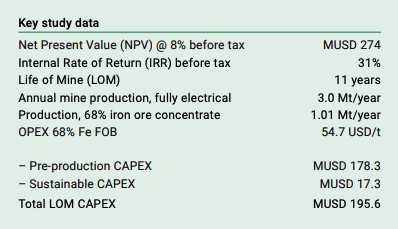

The feasibility study

On 16 December 2022, the feasibility study for the Dannemora project was published, marking the end of the study phase and the starting point for the implementation phase, which begins in the first quarter of 2023.

The positive results presented in the feasibility study show that a very high iron ore concentrate can be produced at Dannemora, most likely over a more extended production period than what was shown in the feasibility study, and probably with the lowest carbon footprint in the market.

Thus, another important milestone for reopening the Dannemora mine has been passed. The port of export has been changed to Oxelösund as this allows to costeffectively expand relevant markets and reach customers in the Middle East and North Africa. The project is now entering the implementation phase, initially with project preparations, such as detailed design, organisational development, and critical procurement to be ready to initiate the construction works once the environmental permit is obtained.

Based on the development of the new beneficiation process during the study phase, which enables the beneficiation of raw ore with lower iron grades, a systematic relogging of existing drill cores in the Dannemora drill core archive has been carried out. The result is that the mine’s production life has been extended to 11 years. The relogging work continues in 2023.

» MOST OF THE INTERPRETED MINERALISED ORE BODIES HAVE EXPLORATION POTENTIAL AS THEY ARE OPEN AT DEPTH «

A sustainable underground mine with 100% electrified operation

100% electric machinery underground will improve working environment and reduce emissions. The mine has previously been updated with modern infrastructure for a modern mining operation.

The large emissions of carbon dioxide underground in Dannemora were during the previous operating period, for example, when removing rock for preparation and crude ore production, passenger and crude ore transport, and up-transport of crude ore to the beneficiation plant. The planned underground production strives to be completely carbon dioxide-free.

The large emissions above ground previously came from unloading and transport of ore product to Hargshamn. The operation of the enrichment plant will be fully electrified and the outbound transport by train will be hydrogen-powered and thus completely carbon dioxide-free.

Increased demand for iron ore

We plan to restart the production of iron ore in the Dannemora mine. The subsequent beneficiation process is adapted to meet the expected large increase in demand for iron ore concentrates with iron contents above 67% which primarily arises through the environmentally sustainable conversion of the fully integrated steel mills in Europe. Dannemora’s magnetite concentrate, with an iron content of approx. 68%, belongs to the world’s absolute top layer in terms of iron content. Its other chemical properties are also to be considered attractive for steel producers with ambitions to produce green steel. Iron ore is mainly used to produce iron and steel. Steel is used more than 20 times more than all other metals combined, according to Svemin.

The mine’s geographical location is unique from a European point of view with access to two alternative export ports within 4-9 miles of distance and thus the iron ore producer that is closest to the major integrated European steel mills.